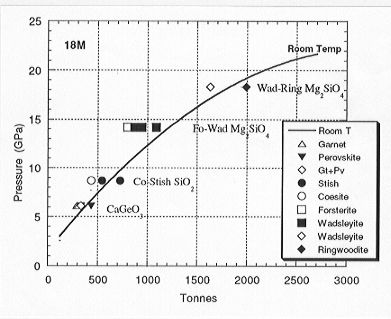

Pressure calibration of a 6-8 type multianvil apparatus is now underway

following the recent installment of a 5000-tonne uniaxial press. The press

frame is 5 meters in height, over 60 tonnes in weight and houses a 960

mm diameter ram with a travel distance of 200 mm. Six outer anvils are

contained within a split cylinder geometry to create a working volume for

eight 54 mm cubic inner anvils made of tungsten carbide. Phase transitions

in silicates, metals and semiconductors were used to calibrate 18-mm (18M)

and 25-mm (25M) edge-length MgO octahedra using 11-mm and 17-mm truncation

edge lengths (TEL) on the tungsten carbide anvils, respectively. Calibration

of the 18M assembly (Fig. 3.8-1) using 5 x 3 mm pyrophyllite gaskets was

carried out at room temperature up to the GaP semiconductor to metal transition

at 22 GPa and required 2660 tonnes. Pressure generation from the Bi I-II

(2.55 GPa) to the Bi III-V (7.7 GPa) is very efficient with applied force,

but efficiency decreases at higher pressures (ZnS at 15.6 GPa, GaAs at

18.3 GPa and GaP at 22 GPa). High-temperature (1000-1200°C) calibrations

have been carried out for the same assembly up to the wadsleyite-ringwoodite

transition at 18 GPa, which required about 2000 tonnes. For the high-temperature

calibration, pressure efficiency was better than at room temperature, beginning

with the CaGeO3 (Gt-Pv) transition at 6 GPa, and continuing

with coesite-stishovite at 9 GPa and forsterite-wadsleyite at 14 GPa, but

curvature was evident in the pressure vs. load plot approaching the wadsleyite-ringwoodite

transition at 18 GPa. Optimization of gasket composition and dimensions

may improve efficiency at these higher applied loads. These results provide

encouragement that it will be possible to increase sample volumes to the

sizes necessary for in situ measurements of physical properties such as

thermal conductivity and ultrasonic-wave velocity, on high-pressure phases

such as ringwoodite and perovskite.

|

Tel: +49-(0) 921 55 3700 / 3766, Fax: +49-(0) 921 55 3769, E-mail: bayerisches.geoinstitut(at)uni-bayreuth.de

Previous page

Previous page